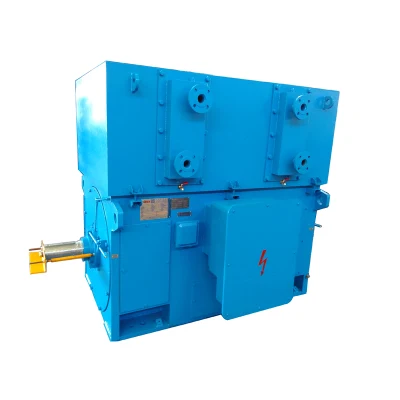

380V-10000V Jr Series Wound Rotor Slip Ring Motor Ball Mill Motor

The JR series motor is a protective winding type rotor three-phase asynchronous motor with cooling method IC01 and conti;

Basic Info

| Model NO. | Jr500L3-6-480kw |

| Application | Industrial |

| Operating Speed | Constant Speed |

| Number of Stator | Three-Phase |

| Species | Jr /Jr2 |

| Rotor Structure | Winding Type |

| Casing Protection | IP23 |

| Number of Poles | 6 |

| Starting Mode | Serial Rotor Resistance Starting |

| Certification | ISO9001, CCC, Ce |

| Brand | China Mtoor |

| Protection | IP23 |

| Voltage | 380V/415V/660V/3kv/6kv/10kv |

| Nsulation Class | F |

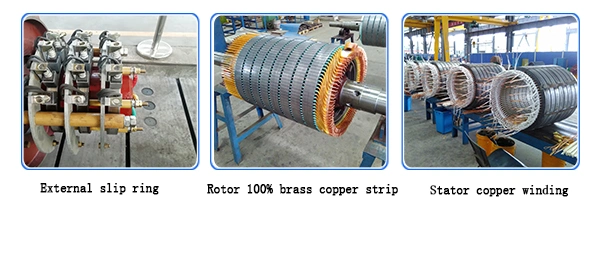

| Stator Winding | 100%Red Copper |

| Driving | Ball Mill,Steel Rolling Mill,Sugar Rolling Mill |

| Cooling Method | IC01 |

| Rotor Winding | 100%Red Copper |

| Advantage | Strong Ability for Instantaneous Overload |

| Frequency | 50Hz/60Hz |

| Transport Package | Plywood Case |

| Trademark | ZCL |

| Origin | Shijiazhuang, China |

| HS Code | 8501530090 |

| Production Capacity | 500 PCS Per Month |

Product Description

The JR series motor is a protective winding type rotor three-phase asynchronous motor with cooling method IC01 and continuous working system (S1). This series of motors can provide a large starting torque at a small starting current and can adjust the speed within a certain range.

The JR winding slip ring motor casing is a cast iron casing or a steel plate welded casing with high structural strength and good mechanical properties. The motor shaft extension end and the non-bearing end have an inlet and outlet air outlet, and the motor slip ring is located at the non-bearing end. The series of motors have simple structure, convenient installation, convenient maintenance, large starting torque and safe and reliable operation. JR winding slip ring motors can drive a variety of different machines, such as fans, compressors, pumps, crushers, ball mills, winches, hoists, transport machinery and other equipment, as well as mines, machinery, power plants and Used as prime mover in various industrial and mining enterprises.

Motor power range: 80KW-850KW

Rated voltage: 380V/415V/660V/690V/3000V/33000V/6000V/10000V

Number of poles: 6/8/10/12

Rated frequency: 50Hz/60Hz

Protection level: IP23

Cooling method: IC01

Working system: S1

Insulation class: B

Wiring method: △

Ambient temperature: ≥ -15 ° C and ≤ 40 ° C

The JR winding slip ring motor is suitable for altitudes up to 1000 m and ambient air temperature is 0-40 degrees. The protective motor should be installed in a room with clean air, no dust, steam, acid, alkali and other corrosive gases. It is not allowed to be used in an environment containing explosive gas or dust.

The JR winding slip ring motor casing is a cast iron casing or a steel plate welded casing with high structural strength and good mechanical properties. The motor shaft extension end and the non-bearing end have an inlet and outlet air outlet, and the motor slip ring is located at the non-bearing end. The series of motors have simple structure, convenient installation, convenient maintenance, large starting torque and safe and reliable operation.

The company has large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

The motor products manufactured and sold by our company are used in many industries, such as electric power, mining, steel metallurgy, petrochemical, water conservancy, transportation, building materials and many other industries. The equipment for the motor is pump, machine tool, fan, mill, crusher, rolling mill, compressor and many other industrial equipment.

1. Professional motor manufacturing service provider;

2. Sound product quality management and certification system;

3. Have a professional sales and technical service team;

4. The motor has perfect process and strong mechanical processing capability;

5. High standard product technical service system;

6, good faith and mutual benefit, good credit guarantee.

You may also like

Send inquiry

Send now