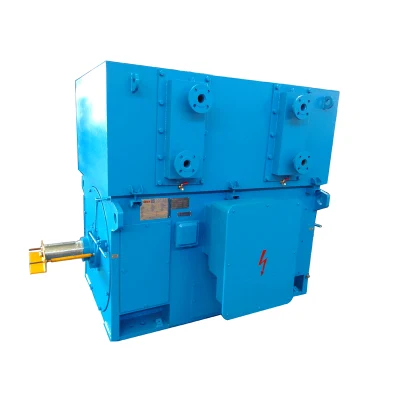

800kw 6000V Yks Series Air-Water Cooling High-Voltage Squirrel-Cage Motor

YKS series (6KV) high voltage motor is a squirrel-cage rotor water-cooled three-phase asynchronous motor. This type of m;

Basic Info

| Model NO. | YKS5603-8-710KW |

| Number of Poles | 8 |

| Starting Mode | Soft Starter |

| Certification | ISO9001, CCC, Ce |

| Brand | China Motor |

| Voltage | 3kv.3.3kv.6kv.6.6kv.10kv.11kv |

| Protection Rating | IP44 or IP54,IP55 |

| Nsulation Class | F |

| Output Power | 800kw |

| Cooling Method | IC611,IC616.IC666.IC81W |

| Duty | S1 |

| Frequency | 50Hz/60Hz |

| Stator Winding | 100% Copper Wire |

| Driving | Pump, Air Compressor,Cone Crusher |

| Transport Package | Plywood Case |

| Trademark | ZCL |

| Origin | Shijiazhuang, China |

| HS Code | 8501530090 |

| Production Capacity | 500 Sets Per Month |

Product Description

YKS series (6KV) high voltage motor is a squirrel-cage rotor water-cooled three-phase asynchronous motor. This type of motor has advanced technology, high efficiency, low noise, low vibration, reliable operation, convenient installation and maintenance. The power class, installation dimensions and electrical performance of this series of motors are in compliance with the relevant provisions of the IEC standard.

The YKS high voltage three-phase asynchronous motor has a protection rating of IP44 or IP54 and a cooling method of ICW81A.

YKS series (6KV) high voltage AC motors can be used to drive a variety of different machines. Such as ventilators, compressors, pumps, crushers, cutting machine tools and other equipment, and can be used for prime movers in coal mines, machinery industry, power plants and various industrial and mining enterprises.

YKS series (6KV) high-voltage water-cooled motor structure and installation type is IMB3. The quota is continuous quota based on continuous working system (S1). The rated frequency of the motor is 50Hz, the rated voltage is divided into 6KV, 10KV, other voltage levels or Special requirements can be agreed with the user when ordering.

This type of high-voltage motor is viewed from the shaft extension end. The 2-pole motor rotates clockwise. If the user needs to rotate counterclockwise, it must be specified when ordering.

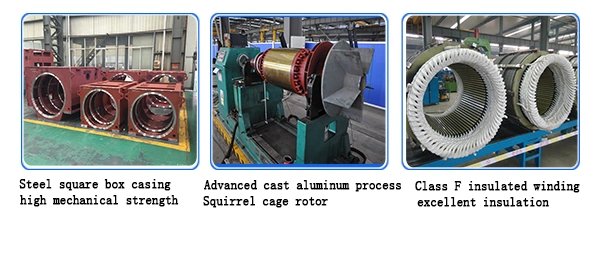

The rotor of the YKS series (6KV) high voltage motor uses a reliable squirrel cage structure of cast aluminum or copper conductor. Bearings are available in both rolling and plain bearings, depending on the speed and power of the motor.

YKS series (6KV) high voltage motors can be used to drive a variety of general machinery, such as: compressors, pumps, fans, crushers, cutting machines, transportation machinery and other mechanical equipment. In the mining, machinery industry, power plants and other industrial and mining enterprises as the prime mover. Used to drag blowers, coal mills, rolling mills, winches, etc. should be stated when ordering.

Center height range: H355 ~ 630mm

Power range: 220kW ~ 2800kW

Number of poles: 2/4/6/8/10/12

Rated voltage: 3000V/33000V/6000V/6600V

Rated frequency: 50HZ/60HZ

Protection level: IP44 or IP54

Insulation class: F

Work system: S1 (continuous)

Cooling method: IC81W

Installation form: IMB3

Motor connection: Y (three outlet terminals in the junction box, the junction box from the extension of the spindle is located on the right side of the base)

Altitude: no more than 1000m

This type of motor is suitable for use in environments where the ambient air temperature does not exceed 40 ° C and there is no serious dust, the minimum ambient air temperature is -15 ° C, and there is no corrosive and explosive gas in the air (which can also be made into a damp heat or high-altitude motor).

YKS series (6KV) high-voltage motor has excellent materials, excellent manufacturing, high efficiency, low noise, low vibration, reliable operation and convenient installation and maintenance. The stator winding of the motor is always made of Class F insulation, and is treated by vacuum pressure immersion solventless paint to make the whole stator of the motor have good integrity, good structural strength, good impact resistance, electrical performance and moisture resistance, and stator winding temperature. It is upgraded according to Class B (80k), which can greatly extend the service life of the motor.

The company has large-scale laboratory, intelligent CNC winding machine, CNC rising machine, automatic wrapping machine, VPI high pressure vacuum immersion system, large-scale dipping paint drying furnace, 60 tons test platform, large vertical car, milling machine, grinding machine, Each type of dynamic balancing machine, double-feedback test and detection system with 6MW (12MW) motor and other motor production professional equipment more than 500 sets, sound mechanical equipment processing capacity, to lay a good foundation for customers to improve good quality motor products.

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

ZCL Electric Motor Technology is a company mainly engaged in the manufacture, research and development and sales of motor products. The company has many types of motor products, including IEC standard motors. It is a professional IEC motor manufacturer. Related motor products have passed the product certification in China, the United States, Canada, Europe, the Middle East and other regions, and the products are exported to all over the world. Companies adhere to the "focus on products, service" business philosophy, is committed to improving the quality of safe motor products and services for customers around the world.

You may also like

Send inquiry

Send now