Jr, Jr2 Series 380 V/6 Kv/10 Kv High and Low Voltage Motor Wound Rotor Slip Ring Motor Ball Mill Motor

YRQ ball mill special winding slip ring motor is a new product motor based on the original JR winding slip ring motor. T;

Basic Info

| Model NO. | JR/JR2/JR5003 |

| Number of Poles | 4.6.8.10.12 |

| Starting Mode | Serial Rotor Resistance Starting |

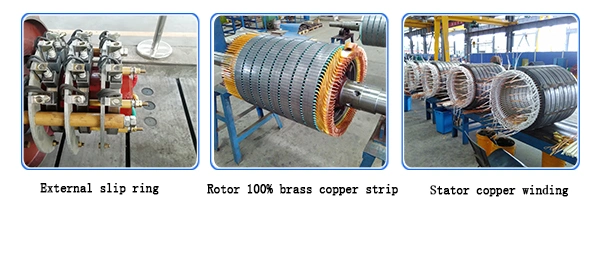

| Certification | ISO9001, CCC, Ce |

| Brand | China Mtoor |

| Protection | IP23 |

| Voltage | 380V/415V/660V/3kv/6kv/10kv |

| Nsulation Class | F |

| Output Power | 380kw--800kw |

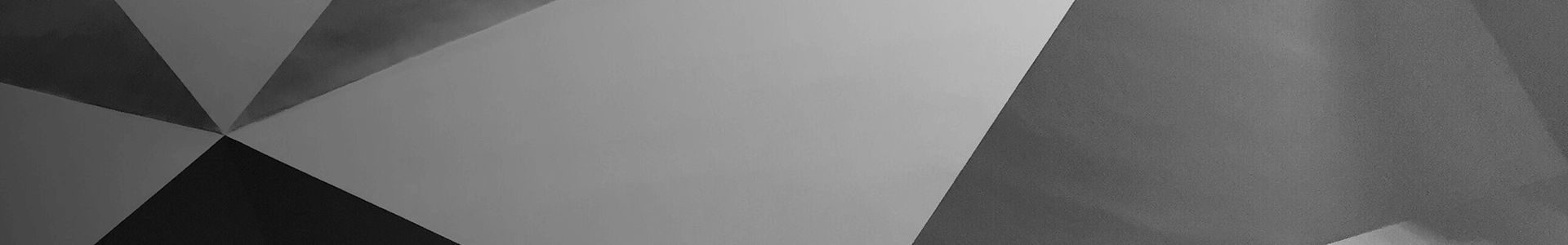

| Stator Winding | 100%Red Copper |

| Driving | Ball Mill,Steel Rolling Mill,Sugar Rolling Mill |

| Cooling Method | IC01 |

| Rotor Winding | 100%Red Copper |

| Advantage | Strong Ability for Instantaneous Overload |

| Frequency | 50Hz/60Hz |

| Transport Package | Plywood Case |

| Trademark | ZCL |

| Origin | Shijiazhuang, China |

| HS Code | 8501530090 |

| Production Capacity | 500 PCS Per Month |

Product Description

YRQ ball mill special winding slip ring motor is a new product motor based on the original JR winding slip ring motor. The motor installation size and power and voltage level are consistent with the original JR motor, ensuring no difference in customer use. . YRQ motors comply with the relevant standards of relevant technical conditions.YRQ ball mill motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation and convenient installation and maintenance.YRQ ball mill motors are widely used in mining machinery, such as ball mills, crushers, etc. It can also drive a variety of different machines, such as fans, compressors, pumps, cutting machines, transport machinery and other equipment.

Motor power range: 380KW-900KW

Rated voltage: 380V/415V/660V/690V/3000V/33000V/6000V/10000V

Number of poles: 6/8/10/12

Rated frequency: 50Hz/60Hz

Protection level: IP23

Cooling method: IC01

Working system: S1

Insulation class: B

Wiring method: △

Installation method: B3 (horizontal installation)

Ambient temperature: ≥ -15 ° C and ≤ 40 ° C

The deviation of the rated voltage of the YRQ ball mill motor does not exceed 5%, the allowable deviation of the frequency is 1%, and the sum of the absolute values of the deviations does not exceed 5%.YRQ ball mill motor adopts rotor string resistance full-voltage start-up, which has the advantages of small starting current, large starting torque, high efficiency, low noise, low vibration, good ventilation performance, reliable operation and convenient installation and maintenance.

The motor products manufactured by our company have obtained the ISO9001 quality management management system certification, passed the CCC/COC, China energy-saving product certification, and passed the certification certificates of CE/UL/IRIS/CAS and other European and American countries. The company strictly improves the quality and efficient motor products and services for users in strict accordance with the requirements of relevant product standards.

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

1. Professional motor manufacturing service provider;

2. Sound product quality management and certification system;

3. Have a professional sales and technical service team;

4. The motor has perfect process and strong mechanical processing capability;

5. High standard product technical service system;

6, good faith and mutual benefit, good credit guarantee.

You may also like

Send inquiry

Send now