Speed 745r/Min Yrkk Hv Slip Ring Induction Motor

The power level, installation dimensions and electrical performance of the HV high-voltage slip ring three-phase asynchr;

Basic Info

| Model NO. | YRKK560-8-560KW |

| Number of Poles | 8 |

| Starting Mode | Serial Rotor Resistance Starting |

| Certification | ISO9001, CCC |

| Brand | China Motor |

| Voltage | 10000V/11000V |

| Nsulation Class | F |

| Output Power | 560kw |

| Cooling Method | IC611/IC616 |

| Protection | IP44 or IP54,IP55 |

| Duty | S1 |

| Frequency | 50Hz/60Hz |

| Stator Winding | 100% Red Copper |

| Rotor Winding | 100% Red Copper |

| Driving | Steel Rolling Mill, Cement Mill,Sugar Rolling Mill |

| Rated Speed | 745r/Min |

| Transport Package | Plywood Case |

| Trademark | ZCL |

| Origin | Shijiazhuang, China |

| HS Code | 8501530090 |

| Production Capacity | 100 Sets Per Month |

Product Description

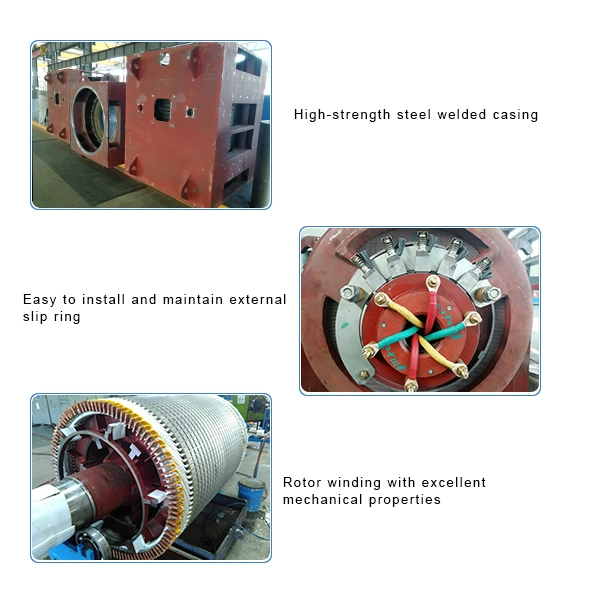

The power level, installation dimensions and electrical performance of the HV high-voltage slip ring three-phase asynchronous motor are in compliance with relevant IEC standards. The basic installation method of the motor is the horizontal bottom angle (IMB3), the working system is the continuous working system (S1), and the wound rotor is made of Class F insulation material.The bearing of HV wound rotor slip ring motor has two types of rolling bearing and sliding bearing, depending on the motor power and speed. If the motor has a high degree of protection, the protection level of the bearing will also increase. The rated frequency of the motor's power supply is 50Hz, the rated voltage is 6000V/10000V, and the basic type of protection is IP54. The motor slip ring housing can be protected to IP22 or IP23. Other voltage, frequency and degree of protection motors are also available upon request.HV winding rotor slip ring motor main outlet box is IP54 protection grade, generally installed on the right side of the motor (facing the motor shaft extension end), can also be installed on the left side of the motor according to the order requirements. Inside the main outlet box, outside There are separate ground terminals.HV winding slip ring motor increases the setting and bearing temperature measuring device. It can also add heating device inside the motor. The shaft extension key of the motor generally adopts the tangential key, and the motor carbon brush is not lifting structure.HV wound rotor slip ring motor can be used to drive a variety of different machinery, such as compressors, pumps, crushers, cutting machine tools, transportation machinery and other mechanical equipment, in mining, machinery industry, petrochemical industry, power plants, etc. Used as prime mover in various industrial and mining enterprises. The motor used to drive the blower, coal mill, rolling mill and winch should indicate the purpose and technical requirements when ordering, and adopt special design to ensure reliable operation.Center height range: H355 ~ 1000mmPower range: 220kW ~ 10000kWNumber of poles: 2/4/6/8/10/12Rated voltage: 3000V/6000V/6600V/10000V/11000VRated frequency: 50HZ/60HZProtection level: IP23 or IP44Insulation class: FWork system: S1 (continuous)Cooling method: IC01/IC611Installation form: IMB3Motor connection: Y (three outlet terminals in the junction box, the junction box from the extension of the spindle is located on the right side of the base)Altitude: no more than 1000mThis type of motor is suitable for use in environments where the ambient air temperature does not exceed 40 ° C and there is no serious dust, the minimum ambient air temperature is -15 ° C, and there is no corrosive and explosive gas in the air (which can also be made into a damp heat or high-altitude motor).

No. | Squirrel-cage motor | Y JS | YKK | YKS | Y2, Y3 |

| Slip ring motor | YR JR JR2 | YRKK | YRKS | YR2, YR3 | |

| 1 | Structure | Box-type construction, made up of steel plates welded with each other | Compact struction | ||

| 2 | Cooling method | IC01 or (IC11, IC21, IC31) | IC611 or IC616 | IC81W | IC411 |

| 3 | Natural ventilation, with top mounted protection cover | With top mounted air-air cooler | With top mounted air-water cooler | ||

| 4 | Protection type | IP23 | IP44 or IP54 | IP44 or IP54 | IP54 |

| 5 | Insulation | F | |||

| 6 | Mounting arrangement | IMB3 | |||

| 7 | Voltage available | 380 v, 2400 v, 3kv, 3.3kv; 4160 v, 6kv, 6.6kv; 10kv, 11kv | |||

| 8 | Frequency available | 50Hz , 60Hz | |||

The HV wound rotor slip ring motor can increase the large starting torque at a small starting current. The motor is suitable for applications where the capacity of the feeder line is insufficient to start the squirrel-cage rotor, the starting time is long, the starting is frequent, and the small-range speed regulation is required. This series of motors has the advantages of high efficiency, energy saving, low noise, low vibration, light weight, reliable performance, convenient installation and maintenance.

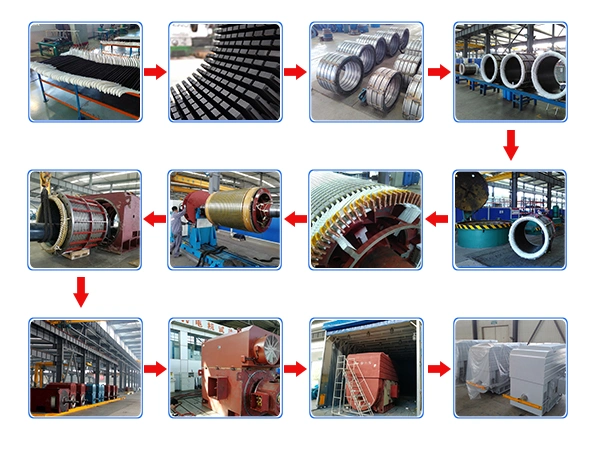

Main process flow of the motorMotor stator: casing processing → punching press → iron core seating → coil making → weaving → dipping paint dryingElectronic rotor: blank shaft processing → iron core press installation → iron core cast aluminum → rotor string shaft → weave → dipping paint drying → dynamic balanceMotor assembly: stator rotor assembly → machine test → motor appearance coloring → packaging storage

1. The outer packaging of the products are all standard export-oriented wooden plywood packaging.

2, the product packaging is protected by moisture, water plastic soft packaging

3. For products with special transportation requirements (such as temperature, fragile, variability, and easy to get wet), the packaging protection measures will be strengthened, and the target mark will be printed on the package.

4. There are obvious signs and symbols on the packing box that must be paid attention to during transportation and storage (such as position, moisture, rain, shockproof, lifting position, etc.).

You may also like

Send inquiry

Send now