Yks Series High-Voltage 3-Phase Asynchronous Water-Cooled Induction Motor

The water-cooled induction motor is a squirrel-cage three-phase asynchronous motor. This series of motors adopts the int;

Basic Info

| Model NO. | YKS5601-2-1120KW |

| Number of Poles | 2 |

| Starting Mode | Direct on-line Starting |

| Certification | ISO9001, CCC, Ce |

| Brand | China Motor |

| Voltage | 3kv.3.3kv.6kv.6.6kv.10kv.11kv |

| Protection | IP44 or IP54,IP55 |

| Nsulation Class | F |

| Output Power | 1120kw |

| Cooling Method | IC611,IC616.IC666.IC81W |

| Duty | S1 |

| Frequency | 50Hz/60Hz |

| Stator Winding | 100% Copper Wire |

| Driving | Pump, Air Compressor,Cone Crusher |

| Transport Package | Plywood Case |

| Trademark | ZCL |

| Origin | Shijiazhuang, China |

| HS Code | 8501530090 |

| Production Capacity | 200 Sets Per Month |

Product Description

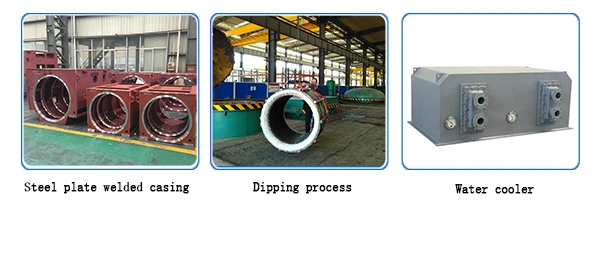

The water-cooled induction motor is a squirrel-cage three-phase asynchronous motor. This series of motors adopts the internationally popular box structure. The base and end cover are made of steel plate welded, which has good rigidity and light weight. After removing the protective cover (or cooler), you can observe and touch the inside of the motor to facilitate the installation and maintenance of the motor. The stator adopts an external press-fit structure. The stator winding adopts F-class insulation material and anti-corona material. The winding end is fixed by a special lashing process, which is firm and reliable. The whole stator is vacuum-impregnated with F-class solvent-free paint (VPI). As a result, the motor has excellent and reliable insulation properties and resistance to moisture and impact.

When the rotor of the high-pressure water-cooled induction motor uses a copper cage rotor, the guide bar and the end ring are welded by medium frequency, and the rotor copper strip is processed by the in-tank fastening process, thereby having high reliability.

The water-cooled high-voltage induction motor rotor coil is made of copper strips and is covered with F-class insulation material. The welding between the coils and between the lead copper strip and the coil is silver brazed to ensure the reliability of the motor operation. The bearing adopts end cap type spherical plain bearing, which has the advantages of strong load capacity and convenient maintenance. The main outlet box is sealed and has a degree of protection of IP54. It is usually mounted on the right side of the motor (from the shaft end) and can be mounted on the left side according to user needs. The cable entry hole of the outlet box can be switched upwards, downwards, left and right. There is a separate ground terminal in the box. When the motor power is 2000 kW or more, a secondary outlet box is also provided on the other side of the motor opposite to the main outlet box for taking out the neutral point of the stator three-phase winding.

Center height range: H355~1000mm

Power range: 185kW to 12000kW

Number of poles: 2/4/6/8/10/12

Rated voltage: 3000V/3300V/6000V/6600V/10000V/11000V

Rated frequency: 50HZ/60HZ

Protection level: IP54 or IP55

Insulation class: F

Work system: S1 (continuous)

Cooling method: IC81W

Installation form: IMB3

Motor connection: Y (three outlet terminals in the junction box, the junction box from the extension of the spindle is located on the right side of the base)

Altitude: no more than 1000m

This type of motor is suitable for use in environments where the ambient air temperature does not exceed 40 ° C and there is no serious dust, the minimum ambient air temperature is -15 ° C, and there is no corrosive and explosive gas in the air (which can also be made into a damp heat or high-altitude motor).

The water-cooled induction motor adopts the internationally popular box structure, and the base and the end cover are all welded by steel plates, which have good rigidity and light weight. After removing the protective cover (or cooler), you can observe and touch the inside of the motor to facilitate the installation and maintenance of the motor. The stator adopts an external press-fit structure. The stator windings are made of Class F insulation material and anti-corona material. The winding ends are fixed by a special lashing process, which is firm and reliable. The whole stator is treated with vacuum pressure impregnated Class F solventless paint (VPI). Thus, the motor has excellent and reliable insulation properties and moisture and impact resistance.

The motor products manufactured by our company have obtained the ISO9001 quality management management system certification, passed the CCC/COC, China energy-saving product certification, and passed the certification certificates of CE/UL/IRIS/CAS and other European and American countries. The company strictly improves the quality and efficient motor products and services for users in strict accordance with the requirements of relevant product standards.

There are many types of motor products manufactured and sold by our company. The main products are high- and low-voltage three-phase asynchronous motors. The motor structure types include squirrel-cage type and winding type. Among them, high-voltage synchronous motors mainly support air compressors and mine ball mill equipment. use. We adhere to the service tenet of "focus on products, service with heart" and provide high-quality motor products to customers.

Our company's motor manufacturing factory adheres to the concept of green, efficient and energy-saving production service, pays attention to the harmonious development of internal and external environment, builds environmentally friendly motor manufacturing enterprises, strictly implements motor standard process, and selects high-quality energy-saving materials to ensure the quality of motor products.

You may also like

Send inquiry

Send now